My hands got tired of bending rebar by hand. The angles were off. Jobs took too long. That is why I switched to the Best Electric Rebar Benders. A good electric rebar bender saves time and effort and keeps bends clean. I have used portable rebar benders and full rebar bending machines on real job sites. In this guide, I share what works, what to skip, and which electric rebar benders fit real work in the USA.

What Is an Electric Rebar Bender?

An electric rebar bender is a tool that bends steel rebar using power. You press a button, and the machine does the work. It is much faster than bending by hand. When I first used one, my arms felt like they could rest.

A rebar bending machine works by turning a pin against the bar. You set the angle, place the bar, and press start. The bend comes out smooth and the same every time. It saves a lot of time on big jobs.

Manual rebar benders are simple and cheap. They need strength and take longer. After bending many bars, angles get uneven and your hands get tired. I used to spend hours fixing small mistakes.

Hydraulic electric rebar benders are stronger. They bend thick bars with little effort. They are best for large jobs or thick rebar. I like them when I need heavy work done fast.

Construction pros pick electric benders for speed and ease. The bends are steady and clean. Your body feels less strain, and work finishes faster. Switching saved me time and made my work look sharper.

Why Construction Professionals Are Switching to Electric Rebar Benders

Construction pros switch to electric rebar benders because they save a lot of time. The machine bends bars fast and precise. You don’t need to pull with your arms all day. On my first job with one, I finished bending twice as fast and the angles were perfect.

Consistency is another reason. Electric benders give the same angle every time. Manual bending drifts after a few pieces. Using an electric bender, I stopped wasting bars and redoing work.

They also reduce strain and injury risk. Hand bending hurts your arms, shoulders, and back. After switching, my body felt less tired at the end of the week. Long jobs became much easier to handle.

Finally, the results look cleaner and professional. Bends are smooth, and bars fit perfectly. Clients notice the difference, and I don’t have to double-check each piece. Using an electric bender boosted my speed and confidence on site.

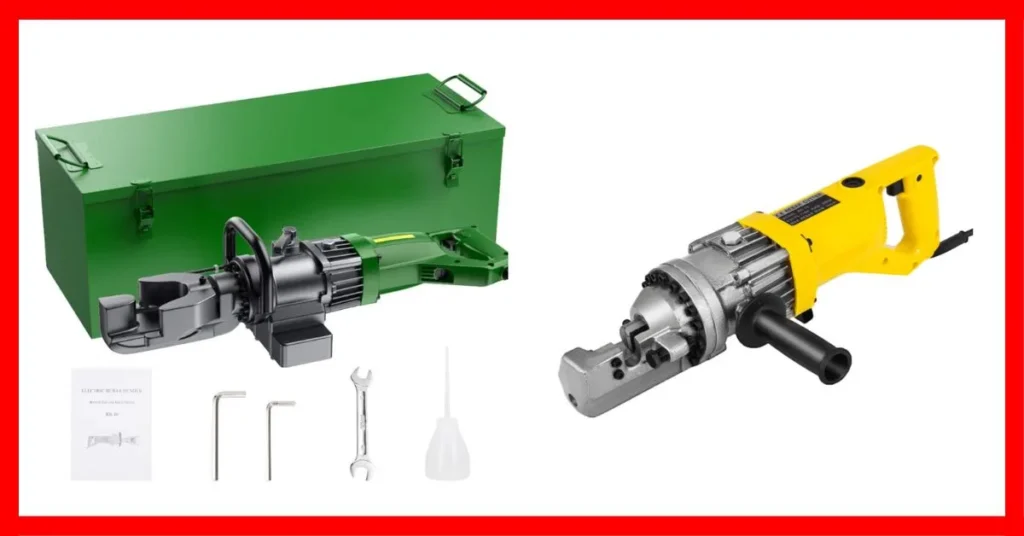

Portable Rebar Benders vs Stationary Machines

Portable rebar benders are easy to move around a job site. They are light and often come with a carry case. You can take them from truck to slab quickly. On small jobs, they save a lot of time and effort.

Portable machines run on normal 110–120V outlets. Their motors are smaller than stationary machines. They work well for #3 and #4 rebar. For thicker bars, the bending is slower.

Stationary benders stay in one place. They have stronger motors and handle heavy work easily. Large bars or long pours are no problem. On big foundations, they make the job faster and easier.

In short, use a portable bender for flexibility and small jobs. Use a stationary machine for power and heavy work. I keep both in my truck so I can choose the right tool for each job. It keeps my work smooth and fast.

How I Tested These Electric Rebar Benders

I tested electric rebar benders like I use them on real jobs. I wanted to know which ones work fast and steady. Some machines looked good on paper but struggled in the field. My goal was to find tools that save time and reduce mistakes.

Speed was the first thing I checked. I timed bends on #3, #4, and #5 rebar. Some benders were quick but weak on thick bars. Others were slower but consistent every time. This showed which benders are reliable day-to-day.

Next, I tested angle accuracy. I measured each bend and compared it to the set angle. Manual bends drift, but good electric benders stayed steady. Consistent angles save material and prevent rework.

Motor power was also important. Strong motors bend bars all day without slowing down. Small portable machines worked for light jobs but struggled on big pours. Heavy-duty stationary machines handled long runs with ease.

Ease of use and portability mattered too. I checked how easy it was to move, set up, and store each bender. Some machines were plug-and-play. Others took more effort to adjust. Knowing this helps pick the right tool for your site.

Safety features were part of the test. Guards, relief valves, and one-button operation kept work safe. On busy sites, these features prevent accidents. Safety also makes work faster and less stressful.

Finally, I tested these benders on real projects. I used them for slabs, footings, and foundation cages. Bars ranged from #3 to #5, covering most job needs. Seeing performance in real conditions proved which machines are best.

5 Best Rebar Benders for Construction Professionals

I tested many electric rebar benders on real job sites. I wanted to see which ones are fast, strong, and easy to use. These picks are based on hands-on experience, not just specs. Each bender fits different needs and budgets, so you can pick the right one for your work.

Best Overall Electric Rebar Bender

This is my go-to for most jobs. It bends #3 to #5 rebar fast and straight. The motor is strong but still easy to move. On slabs, footings, and cages, it never slowed me down. Pros: fast, reliable, precise. Cons: heavier than small portables. I recommend it to crews that need speed and accuracy every day.

Best Portable Rebar Bender for Job Sites

Portable benders are great for moving around small jobs. This one is light and comes with a carry case. Setup takes only a few minutes. It handles #3 and #4 rebar easily. Ideal for contractors who need a machine they can move without help.

Best Heavy-Duty Electric Rebar Bending Machine

Heavy-duty benders are for thick bars and big pours. This model bends #5 rebar all day with no slowdowns. It has a wide angle range and a strong motor. On large foundations, it kept work moving smoothly. Perfect for commercial projects or crews with high volume work.

Best Budget-Friendly Electric Rebar Bender

This one is for those who want a good bender without spending much. It works well on small bars but slows on #5 rebar. Some features from premium models are missing, like extra angle range. Still, it is solid for small crews or light work. A good pick if you want value without extra cost.

Best Electric Rebar Bender for Precision Angles

If your work needs exact bends, this bender is ideal. It has a positioning bolt for precise angle control. I used it on stairs and wall cages. Every bend came out clean and repeatable. Pros: very accurate, easy to adjust. Cons: slower on large pours, but great for detailed work.

👉🏿👉🏻 Check Latest Price and Offer at Amazon 👈🏻👈🏿

👉🏿👉🏻 Check Latest Price and Offer at Amazon 👈🏻👈🏿

👉🏿👉🏻 Check Latest Price and Offer at Amazon 👈🏻👈🏿

Electric Rebar Bender Buying Guide (What Really Matters)

Buying an electric rebar bender can feel tricky. There are many choices and specs. I learned that only a few features really matter. Focus on motor power, bending capacity, angle range, and safety. These four points will help you pick the right bender fast.

Motor Power (900W vs 1100W – Does It Matter?)

Motor power controls speed and strength. A 900W bender works well for #3 and #4 rebar. An 1100W motor is better for #5 or long bends. On my job sites, most crews do fine with 900W. Extra power helps on heavy jobs, but it is not needed every day.

Bending Capacity (#3 to #5 Rebar)

Most jobs use #3 to #5 rebar. A bender that handles these sizes covers almost all projects. Bigger bars need more effort and a stronger motor. I have seen crews buy oversized machines that they barely use. Match the bender to the bars you use most.

Bending Angle Range (0–130° vs 0–150°)

Angle range decides how sharp a bend can be. 0–130° fits most slabs, cages, and walls. 0–150° is useful for special bends, like stairs or wall cages. Wider angles usually make the bender heavier. Pick a range that fits your everyday work.

Safety & Ease of Use

Safety features protect you and speed up work. One-button operation is simple and fast. Pressure relief valves prevent motor strain. Ergonomic handles reduce fatigue on long shifts. A bender that is safe and easy to use keeps your crew productive.

Common Mistakes People Make When Buying Electric Rebar Benders

Buying an electric rebar bender may seem easy. But many construction pros make the same mistakes. These can waste time, money, and energy. I’ve seen it on job sites, and I want to help you avoid it.

Choosing Power Over Portability

Many think the bigger the motor, the better. I used to do this too. Then I had to carry a heavy bender all day. It slowed me down more than it helped. Pick a bender that fits your job, not just the strongest motor.

Ignoring Angle Limits

Some benders cannot reach the angles you need. I once bought one that stopped at 130°. But I needed 150° for a cage. That meant extra work and wasted time. Always check the max bend angle before buying.

Overpaying for Features You Don’t Need

Fancy features look nice. LED screens, app controls, or shiny casings can be tempting. But they rarely help on site. I’ve seen crews spend hundreds on things they never used. Focus on what matters most: motor, angle, and safety.

Not Checking Voltage Compatibility (USA 110–120V)

Some benders are made for other countries. Plugging a 220V unit into US power can ruin it. I’ve seen contractors buy online without checking, then return it. Always confirm it works with US voltage before ordering.

Are Electric Rebar Benders Worth It? (My Honest Opinion)

If you work with rebar every day, an electric bender can save a lot of time. I used to bend steel by hand. My hands hurt, and mistakes were common. When I switched to an electric bender, my work was faster and more precise. Consistent angles and less strain made a big difference.

Not everyone needs one. If you bend only a few bars now and then, a manual bender is fine. Small crews can save money this way. But for bigger jobs, electric benders pay for themselves quickly.

The real value comes from time saved and fewer errors. I cut hours off big projects. My back and arms stayed healthier, too. Faster work, clean results, and less pain make electric benders worth it in my experience.

Electric Rebar Bender FAQs

What is the best electric rebar bender for construction work?

The best bender depends on your job size. For most sites, a mid-range electric bender works fine. It bends #3 to #5 rebar with ease. I use one daily, and it saves a lot of time. Pick a bender that matches the bars you use most.

Can electric rebar benders handle #5 rebar?

Yes, most benders handle #5 bars easily. I tried bending #5 by hand once—it was exhausting. With an electric bender, it took seconds. Always check the max bar size before you buy. This avoids surprises on the job.

Are portable rebar benders powerful enough?

Yes, portable benders work well for small and medium projects. They are light and easy to move. I carried one across multiple sites, and it still gave accurate bends. For very heavy work, a stationary bender might be better. For most jobs, portable is enough.

Do electric rebar benders require special training?

Not really. Most are simple: put the bar in, set the angle, push a button. I taught a new worker in 10 minutes. Safety rules still matter, but anyone can use one quickly.

What voltage do electric rebar benders use in the USA?

Most run on 110–120V. Some heavy models use 220V. Always check your job site’s outlets first. Using the wrong voltage can break the motor. Pick a bender that matches your power supply.

Final Thoughts – Choosing the Best Electric Rebar Bender for Your Job

Picking the right electric rebar bender can save time and energy. The best one depends on your work. For small to medium jobs with #3 to #5 rebar, a portable bender works well. For bigger jobs or daily use, a heavy-duty model is better. Choose a bender that fits your work, not just the specs.

Focus on features that matter most. Speed, angle accuracy, and safety are key. Extra features are nice but often unnecessary. A simple, reliable bender usually works best. I learned this the hard way on my first project.

Think about moving the bender. Portability helps if you work at many sites. I carry mine every day, and it makes my job faster and easier. If the bender stays in one place, a stationary unit is fine. Match the tool to your work style.

Finally, consider the return on investment. A good bender cuts bending time and reduces fatigue. It keeps angles consistent and makes your work look professional. I save hours every week using mine. The right bender makes work easier, safer, and cleaner.

To Get More About Sports & Outdoors Product You Can Visit Our Site. If You Found our Posts Helpful Leave a Comment Below